Dây Chuyền Máy Sấy Công Nghiệp

9.999.999₫

315 Trường Chinh, Khương Thượng, Đống Đa, Hà Nội, Việt Nam

NGUYỄN VINH XIN KÍNH CHÀO QUÝ KHÁCH

LÀ NHÀ PHÂN PHỐI TẠI VIỆT NAM CỦA

TẬP ĐOÀN HOSOKAWA MICRON CORPORATION

XIN GỬI TỚI QUÝ VỊ DÂY CHUYỀN SẢN PHẨM MÁY NGHIỀN SẤY SIÊU MỊN

- ỨNG DỤNG TRONG CÁC NGÀNH KHOÁNG SẢN, THỰC PHẨM, MỸ PHẨM, HÓA CHẤT VÀ DƯỢC PHẨM

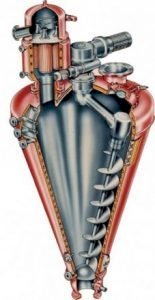

Direct Heating Flash Dryer - Drymeister DMR-H

Máy sấy nóng trực tiếp

- Combination of drying, de-agglomeration/milling and classifying in one piece of equipment.

- High drying ability and no adhesion inside.

- Fine and dry product.

- Easy control of particle size.

- Easy control of moisture content in the product.

- Compact installation.

- High energy efficiency.

- Various options:

- Construction material of ceramics for the powder contact parts.

- Specially designed screw feeder for cake material.

- Compared to conventional Drymeister, DMR-H can:

- induce inlet air temperature up to 600°C

- increase capacity by 40%

- improved thermal capacity coefficient.

Multipurposed-Domed Type with Jacket

Hosokawa Vrieco Nauta Vacuum Dryer

DBX-RWV,NXV

Máy sấy chân không với lớp phủ

- High heat transfer coefficient : Material dependence, but normally U=50-2000W/(m2•K)

- Low energy consumption.

- ca. 5.5-13kW for 2,000 liter/batch size.

- Limited gas tight part.

- Easy discharge and very little residue in the vessel.

- Easy to clean.

Indirect Heating Agitating Media Dryer

Xerbis XB - Máy sấy gián tiếp

- Slurries/Solutions can be directly dried.

- Drying slurries with high viscosity and cohesive nature.

- Energy saving.

- With a closed circuit system, running cost can be drastically reduced.

- Wear protection.

Lyophilisation - Máy sấy khô lạnh / đông khô

Active Freeze Dryer AFD

- Efficient and contamination-free.

- Faster and less labor intensive than the traditional tray freeze drying process.

- High Quality.

- Compact.

- Typical applications include pharmaceuticals like antibiotics, proteins, collagen and API’s, and food & food additives.

Indirect Heating Dryer - Thermo Processor MTD.

Máy sấy nhiệt gián tiếp MTD

- Wide application with different rotor designs.

- F type has higher plug flow property suitable for low moisture material.

- M type has higher mixing ability suitable for sludge like material.

- High heat transfer efficiency.

- Reduce adhesion due to dual rotor construction.

- Compact unit with large heat transfer area.

- Large heat transfer capacity and heat transfer coefficient.

Indirect Heating Dryer - Solidaire SJ

Máy sấy nhiệt gián tiếp

- High dispersion effect enables to dry high moisture content material and caked material to product moisture content to several %.

- Paddles break the agglomerates contained in the material and avoids secondary agglomeration generated while drying to produce powdery products.

- Drying time can be controlled by adjusting angles of paddles and/or rotating speed of rotor.

- With inert gas operation such as N2 as a carrier, it is possible to operate.

Indirect Heating Dryer - Torusdisc TD

Máy sấy gián tiếp TD

- Compact structure with large heat transfers area. Reduced heat loss to outside, and effective use of heat energy.

- High heat transfer coefficient.

- Dry powder, heat transfer coefficient is 20-35kJ/m2•h•K

- Wet powder; 30 – 60kJ/m2•h•K

- Slurry, 60 – 230kJ/m2•h•K.

- Wide operating application for drying, heating, cooling, vacuum drying and combined operation with hot air.

XIN VUI LÒNG LIÊN HỆ

TEL: 094 588 1362

EMAIL: Hosokawamicronvina@gmail.com

,

HẾT HẠN

| Mã số : | 16025956 |

| Địa điểm : | Toàn quốc |

| Hình thức : | Cần bán |

| Tình trạng : | Hàng mới |

| Hết hạn : | 13/08/2020 |

| Loại tin : | Thường |

Bình luận